Troubleshooting Your Insinkerator: A Step-by-Step Guide for Food Waste Disposal Woes

Imagine you're in the middle of preparing a delightful Sunday roast, and suddenly, your Insinkerator decides to play up. The frustration of dealing with a malfunctioning food waste disposer can be quite the buzzkill. But fear not! This guide will walk you through the troubleshooting process, so you can swiftly get back to your culinary masterpiece without a hitch. With a little bit of knowledge and some practical steps, you'll have your Insinkerator humming like new in no time.

Ever wondered why your Insinkerator sometimes grinds to a halt, leaving you in a bit of a sticky wicket?

Key Takeaways

- Get to grips with the basics of how your Insinkerator operates

- Identify common issues that may cause your food waste disposer to misbehave

- Learn to troubleshoot power supply problems with ease

- Discover how to clear blockages and deal with unusual noises effectively

- Know when it's time to call in the professionals for help

Insinkerator Garbage Disposal Basics

Let's start with the fundamentals. Your Insinkerator, a staple in many British homes, is a nifty device designed to make kitchen clean-up a breeze. But to truly master its use, it's vital to understand how it works and what makes it tick.

At its core, the Insinkerator unit functions by grinding food waste into small particles. This ingenious mechanism allows for easy disposal through your plumbing system. Imagine it as a tiny, efficient factory right under your sink. The process begins when you flip the switch, activating the motor. This powerhouse drives the grinding components to break down waste efficiently. It's not just brute force, though; water plays a crucial role by flowing through the unit, helping to flush away those ground-up particles.

But what happens when things go awry? Safety features come into play. If the unit senses a malfunction, it shuts off to prevent damage. This built-in precaution ensures that your Insinkerator stays in top-notch condition, safeguarding both the unit and your peace of mind.

Components of the Insinkerator disposer are:

- The grinding chamber: where food waste is pulverised into tiny bits.

- The motor: driving the entire process.

- The splash guard serves a dual purpose: it keeps messes at bay by containing waste within the unit, and it also acts as a barrier against stray utensils attempting a daring escape into the grinder.

- Reset buttons and switches

Common Food Waste Disposal Issues

Even the most reliable gadgets can have their off days. Let's dive into some common problems that might plague your food waste disposal unit.

Clogs are a frequent foe. Fibrous materials like onion skins or grease build-up can lead to blockages that hinder the food waste disposer's performance. You'll know there's a problem

when the water refuses to drain away as it should. But that's not all—overloads can cause the unit to go on strike, jamming or shutting off unexpectedly.

Unusual noises can be a telltale sign of trouble. If your Insinkerator starts making a racket, it might have swallowed something it shouldn't have, like cutlery. And let's not forget about odours. Trapped food particles or residue can lead to unpleasant smells wafting through your kitchen, making it a less-than-desirable place to be.

A malfunctioning Insinkerator can be a right pain, but knowing the symptoms can help you act swiftly. If the unit fails to start or makes no sound when switched on, it might be sulking due to a lack of power or a mechanical issue. Slow drainage is another red flag, hinting at a potential blockage in your disposal unit.

When the grinding performance takes a nosedive, leaving larger waste particles behind, it's time to investigate further. And if you're finding yourself resetting the unit more often than not, it could be an indicator of underlying mechanical problems that need attention.

Checking for Power Supply

Before diving into more complex troubleshooting, it's worth checking the basics - like whether your Insinkerator is getting the juice it needs.

First things first, ensure the power switch is on and doing its job. Sometimes, a simple flick can make all the difference. If that doesn't do the trick, it might be worth checking the circuit breaker. A tripped breaker could be cutting off power to your unit, leaving it feeling neglected.

Loose connections are another common culprit. Inspect the wiring and connections to ensure everything is snug as a bug. And don't overlook the obvious—a functional power outlet is essential for your Insinkerator to spring into action.

If your Insinkerator is still giving you the cold shoulder, it's time to dig a bit deeper. Check if the wall socket is playing nice by plugging in another appliance. If that works, the issue might lie elsewhere. Inspect the plug and cord for any visible signs of damage. A frayed cord or damaged plug could be the root of your woes.

Resetting the circuit breaker is another step worth trying. It can often restore power and bring your Insinkerator back to life. If fuses are involved, consider replacing any that might be blown. A steady power supply is crucial for your unit's operation.

Resetting the Insinkerator

When your Insinkerator throws a tantrum, a reset might just do the trick. It's like giving it a gentle nudge to remind it who's boss.

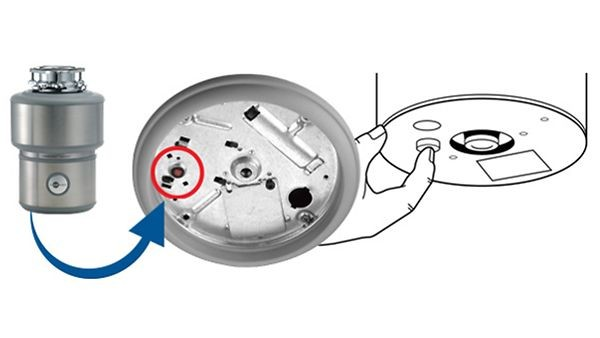

Resetting your Insinkerator is a straightforward process, and it can often resolve minor hiccups. Start by locating the reset button, usually found at the bottom of the unit. Give it a firm press to re-engage the motor. But patience is key—allow the unit to cool down if it overheated. Once it's had a breather, test it by running water and switching it on again.

Resets can work wonders for minor jams or when the unit has shut down due to overload. If overheating caused the shutdown, a brief cooling period followed by a reset can often do the trick. However, frequent resets might be a sign of more serious underlying problems. If your troubles persist, it might be time to consider seeking professional help.

Clearing Blockages in the Disposer

When your Insinkerator seems stubbornly blocked, it's time to roll up your sleeves and tackle the issue head-on.

Slow drainage is a dead giveaway that you're dealing with a blockage. Before you dive in, though, remember to turn off the power. Safety first! With a trusty torch in hand, inspect the grinding chamber for any visible obstructions. Sometimes, the culprit is right there, waiting to be discovered.

If the blockage is minor, running cold water while using a plunger can often do the trick. A few firm plunges can dislodge smaller blockages and get things flowing smoothly again.

When it comes to clearing blockages, having the right tools can make all the difference. A torch is your best friend for illuminating the interior of the disposer. It helps you spot any lurking obstructions. A plunger is another essential tool. Its suction power can effectively dislodge stubborn clogs.

For larger objects, tongs or pliers are your go-to tools for safe removal. And if the blades are jammed, a hex wrench can be used to manually rotate them, freeing any stubborn jams.

Dealing with Unusual Noises

Noises from your Insinkerator can be unsettling, but they often hold clues to what's going on beneath the surface.

Not all noises are created equal. Grinding noises are normal, but they should be consistent and smooth. Rattling sounds, on the other hand, might suggest foreign objects have made their way into the unit. Humming without grinding is a sign of a jammed motor, while squealing or screeching often points to worn or damaged parts.

When your Insinkerator starts singing an unusual tune, it's time to take action. Start by inspecting the grinding chamber for any foreign objects causing the noise. Sometimes, a quick peek is all it takes to spot the offender.

If the unit is jammed, use a hex wrench to manually rotate the blades and free any obstructions. Tightening loose components can also help eliminate rattling sounds. But if the noises persist despite your best efforts, it might be time to call in the professionals.

Maintaining Your Insinkerator

Proper maintenance is the key to keeping your Insinkerator running smoothly and avoiding future headaches.

Running cold water during and after use is a simple yet effective way to clear waste and prevent clogs. Avoid disposing of fibrous or starchy foods, as they can be a recipe for disaster. Instead, dispose of them in the bin to keep your unit happy.

Cleaning the unit monthly with a mixture of ice and vinegar can work wonders. The ice helps dislodge debris, while the vinegar freshens things up. Regular inspections and replacing worn parts as needed ensure that your Insinkerator continues to perform at its best.

Educating household members on proper waste disposal practices can go a long way in preventing future issues. Schedule routine checks to ensure that all components are secure and in good working order. Avoid overloading the unit with excessive waste at once, as this can lead to jams.

Keeping a record of any issues and resolutions is a smart move. It can be a handy reference if problems arise in the future, allowing you to troubleshoot more efficiently.

Contacting Professional Help if Necessary

Sometimes, despite your best efforts, your Insinkerator might need a little extra TLC from the pros.

If you've followed all the troubleshooting steps and issues persist, it might be time to call in the cavalry. Frequent resets or power issues that can't be resolved on your own are clear signs that professional help is needed. Unusual noises that continue despite clearing blockages can also indicate deeper problems.

Visible damage or wear that affects the unit's performance is another red flag. In such cases, seeking professional advice is the best course of action to ensure your Insinkerator returns to its former glory.

The Cattermole Group are the UK's number one repair centre. We are able to offer the customer various levels of service for InSinkErator products - these range from repair services (problem solving) through to providing spares and parts in addition to new products. A professional service is provided every time.

]

In conclusion, while your Insinkerator might throw the occasional tantrum, knowing how to troubleshoot can save you time, money, and a whole lot of stress. With this guide in hand, you're well-equipped to tackle any food waste disposal woes that come your way. Are you ready to become the master of your kitchen's most underrated appliance?

Frequently Asked Questions

Why is my Insinkerator not turning on?

If your Insinkerator is not turning on, first check if it is plugged in properly. If it is plugged in, try resetting the disposal by pressing the reset button located at the bottom of the unit. If the reset button does not work, there may be a larger electrical issue that requires professional assistance.

How do I unclog my Insinkerator?

To unclog your Insinkerator, first turn off the power to the unit. Use a flashlight to look into the disposal to see if there is any visible blockage. If you can see a blockage, use tongs or pliers to remove it. You can also try using a plunger or a disposal wrench to dislodge the clog.

Why is my Insinkerator making a loud noise?

If your Insinkerator is making a loud noise, it could be due to a foreign object stuck in the disposal. Turn off the power to the unit and use tongs or pliers to remove any visible object causing the noise. If the noise persists, there may be a more serious issue with the disposal that requires professional attention.

How do I maintain my Insinkerator for optimal performance?

To maintain your Insinkerator for optimal performance, regularly run cold water while using the disposal to help flush out debris. Avoid putting fibrous or starchy foods, grease, or large bones down the disposal. You can also clean the disposal by grinding ice cubes and citrus peels to keep it smelling fresh.

How do I know when it's time to replace my Insinkerator?

If your Insinkerator is constantly clogging, making unusual noises, or not grinding food waste properly, it may be time to replace the unit. Additionally, if the disposal is leaking or not turning on despite troubleshooting efforts, it is best to consult a professional for advice on whether to repair or replace the Insinkerator.